News to share on our key projects. Our volunteers have put in a lot of time over the winter months, including upgrading yard track that will connect to the workshop, rust repairs for the cab of Ohai Railway Board No.1, repairs and repainting two of our fleet of ballast wagons, Gumdigger carriage frame repairs plus some essential rail vehicle shed work.

Newsletter #40 - September 2019

Newsletter #40 - September 2019

Ballast loading 9 March 2019

A lot of news and progress to share in this latest newsletter issue, Newsletter #40 - September 2019

- Work in progress - July 2019

- Track work - March 2019

- Steam locomotive restoration work February 2019

- Work in progress - December 2018

Chairperson's introduction

There is light at the end of the tunnel, as they say. Shortly we should soon be able to officially open our completed rail vehicle shed and workshop. A huge thank you to the many members and community funders who have helped us over the years in this undertaking.

The completion of the shed enables us as a Trust to focus on vehicle restoration, in particular, the Wb and Ohai No 1 projects which are progressing, see elsewhere in the newsletter for updates on those projects.

Going forward within the Rail Heritage and Tourist movement, inter-group co-operation is essential. A fabulous example of such is the FRONZ Reclaim classified publication, through which we have been able to obtain a number of surplus seat parts and a bogie from Silver Stream Railway, this has been beneficial to both groups. We would recommend the Reclaim to other groups, its a wonderful tool.

Iain Palmer, Chairperson

Tr189 with a passenger service stops short of the rail vehicle shed, 9 June 2019.

During the past couple of months we have upgraded road 4, with a view to operating passenger trains to and from the workshop. We also plan to connect this track into the workshop.

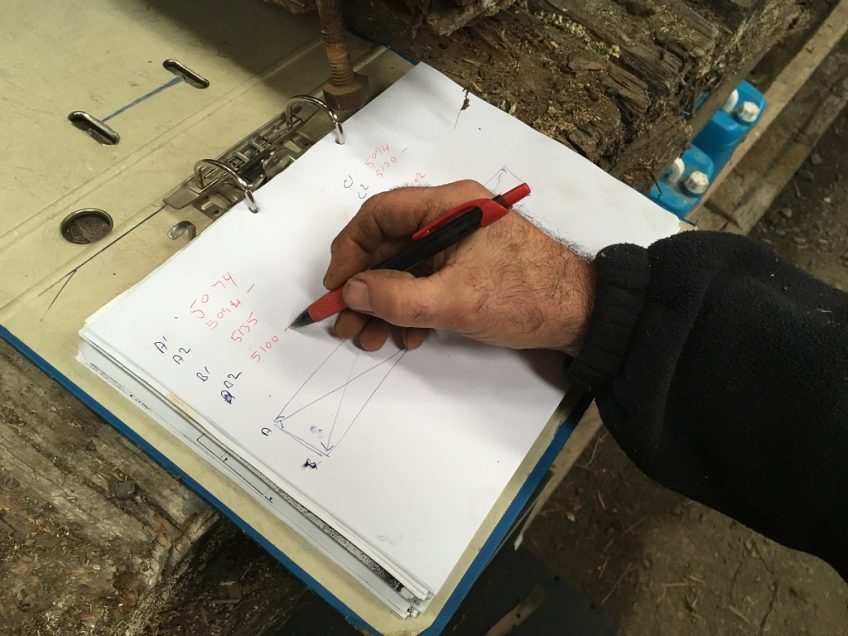

Clive checking one half of the gumdigger carriage A255 for square, one of many checks made after bringing the two halves together.

Detailed measurements are being taken of each carriage body half. Next steps involve presenting new top and bottom plates to the carriage sides, marking out the positions of studs and checking against the drawings.

All going well the new plates will be fitted in the next couple on months.

Colin pointing out areas of the ORB No.1 shunt locomotive cab that need repairs

Patch ready for welding on driver's side of the cab, ORB No.1 shunt locomotive. About a dozen patch repairs are needed on the cab before we can start refitting the long hood frame.

Ray and Ron working on ballast guards of ballast wagon Yc878 on 22 June 2019. The wagon has since been out-shopped.

Ron Jones working on Yc760 on 13 July 2019. This is the latest of our fleet of ballast wagons to enter the "paint shop" for repairs and painting.

Over the weekend of 9 - 10 March 2019 we loaded six ballast wagons, getting ready for track work planned over the Autumn and Winter months.

We're planning to upgrade our 'road 4' track alongside the rail vehicle shed, with a view to its increased use - placing vehicles into the workshop shed, and for our regular monthly operating days.

Loading wagons with ballast stored on the loop formation - which in turn prepares this for track laying.

Loading 'downhill wagons' with ballast for road 4.

Tr189 shunting loaded ballast wagons into the loop.

Track ballasted at end of mainline, Sunday 10 March, with an extension planned over the next couple of months.

Ballast tamped through a joint on road 2 on 10 March 2019. Road 4, left, is next in line for attention. Locomotive Tr189 is pictured shunting vehicles near the workshop shed.

During the warm summer months we took the opportunity to tidy up Baldwin steam locomotive boilers from Wb 292 and Wb 299. Ron Jones and Hugh McCracken cleaned down the steel work, applied two coats of steel primer and a finishing coat of black enamel.

The two boilers were built in New Zealand Railways workshops in the mid-1920s to blueprint y7508, replacing the life-expired original Baldwin boilers dating from 1898. The NZR boilers ran at a higher boiler pressure - 200psi - than the originals, which were rated at a lower 170psi. The 'new' boilers were of similar design to a number other NZR tank locomotives, including Wf, Wg and Ww classes, with many common components and design principles.

Ron priming the backhead of 299's boiler on 5 January 2019.

By 2 February a coat of black enamel had been applied to most of 299's boiler. To the left are the boilers from steam locomotives Wb 292 and Ab 745.

Ron Jones painting firebox top of Wb 299 boiler on 2 February 2019. In the distance the recently completed workshop annex to the rail vehicle shed can be seen.

The clean-up and preparation of components of the two locomotives continues. A set of tank filler castings, comprising base and lid, have been cleaned up and painted. A point of interest in the lid - the pattern number #22609 is incorporated in the casting, picked out in white for the photograph.

Wb locomotive tank filler base cleaned up, after two coats of primer. Next up with be a couple of finishing coats of black enamel and reassembly. The two complete sets are planned to be put on display alongside the locomotive cab, and eventual fitting to new water tanks.

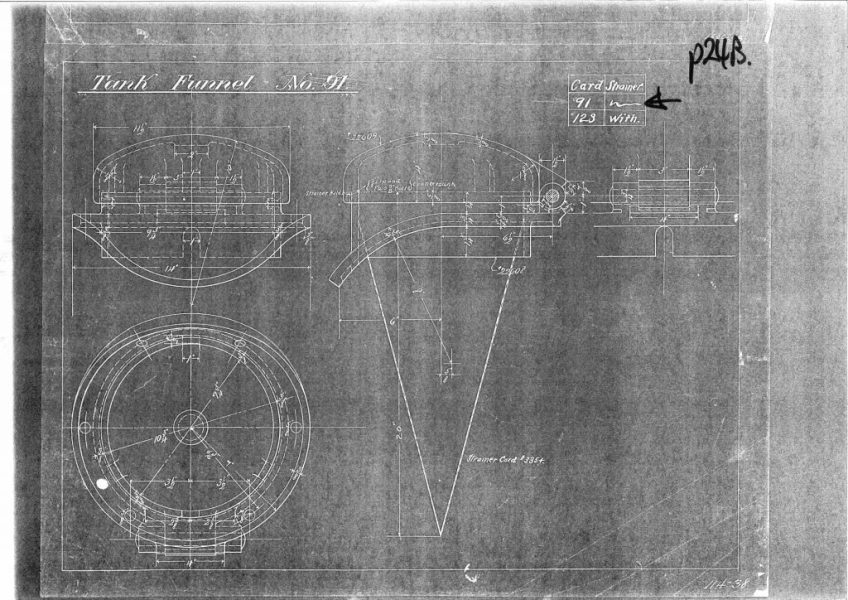

Copy of tank funnel drawing from the book of plans supplied with the Wb class locomotives by Baldwin Locomotive Works. The two castings were each assigned a casting number - the base #22608, and the lid #22609, as seen in the photo of the lid.

Another point of interest in the drawing is the card system employed by Baldwin across the range of locomotive components. The drawing was originally assigned card #91 in 1890, but subsequently a variation card #123 added, to specify the inclusion of a water strainer. Drawings for other components often had long lists of cards, covering variations of key dimensions, finishing required and the incorporation of accessories.

The interior of our rail vehicle shed has been transformed over the past couple of months, with hard fill compacted into place and concrete floors laid. Once completed visitors to our railway will be able to access and view all the rail vehicles in our collection.

We're grateful for funding from Pelorus Trust, Cossie Club Upper Hutt, supporting the effort put in by Trust members.

Back filling inside the rail vehicle shed in October 2018, compacting sub-grade for concrete floors.

Around ten cubic metres of hard fill was needed to prepare the south side of the shed for concrete floors. We hired an excavator to sort and load the fill, working over three days in October.

Placing reinforcing mesh and formwork along the south side of the shed.

A first batch of floor slabs were placed on both sides of the shed in late October.

Second batch of floor slabs, spotted between those laid the previous weekend.

In late November we hired a tracked loader to bring hard fill in to the north side of shed.

Compacting fill into place, north side of shed.

Other progress around the railway - backfilling foundations along the south side of the shed, leveling the ground for access equipment.

A set of heavy-duty shelves have been built to store Ab steam locomotive parts

Ray and Bruce working on the storm water system for the rail vehicle shed, one of a few tasks left to complete the shed.